Precision Levelling wedges

Due to their large contact area Bilz precision levelling wedges (PK) for vibration and structure-borne noise insulation offer optimum support and stiffening of the machine bed.They are available in a wide range of sizes and dimensions as free-standing, bolt-on to the machine or bolt-through to the foundation design.

The proven design principle enables the machine to be quickly leveled to a degree of leveling in the 1/100 mm (0.0004”) range even at loads of 100 tons per wedge.

The powerful self-locking effect of the leveling bolt prevents self-loosening under the effects of vibration. Depending on the application, their use in conjunction with Bilz isolation pads creates the perfect rigidity with very effective vibration isolation.

General information

Bolt-on Bilz precision levelling wedges PKA are used on machines subject to high thrust that require a permanent connection to the machine bed, such as injection moulding machines, slotting ma-chines, extrusion machines etc.

The bolt-on levelling wedges remain in position even when the machine is lifted, significantly easing the installation of the machine.

Note

Plastic injection mouldingmachines, die casting machines, plaining andslotting machines, coldextrusion machines, etc.Extreme slip resistance.

TOP FACE: Plain surface

BOTTOM FACE: Insulation pad B4

Lathes, boring mills, grinding machines and machining centres.

TOP FACE: Plain surface

BOTTOM FACE: Insulation pad BO

| Type | Item no. | max. load | L | B | H | d | e | Internal thread | Adjustment |

| PKA | Centre position | range | |||||||

| N/pc. | mm | mm | mm | mm | mm | mm | |||

| PKA 1-0 | 03/01/07 | 25 | 115 | 115 | 60 | 50 | 24 | M16 | +3/-3 |

| PKA 2-0 | 03/01/10 | 43 | 150 | 150 | 61 | 58 | 23 | M18 | +4/-4 |

| PKA 3-0 | 03/01/24 | 77 | 200 | 200 | 63 | 76 | 27 | M20 | +4/-6 |

| PKA 3/72-0 | 03/01/20 | 77 | 200 | 200 | 87 | 76 | 27 | M20 | +4/-7 |

| PKA 4-0 | 03/01/28 | 97 | 200 | 250 | 87 | 95 | 27 | M20 | +10/-7 |

| PKA 5-0 | 03/01/33 | 161 | 250 | 330 | 87 | 125 | 105 | M24 | +6/-10 |

| PKA 6-0 | 03/01/37 | 236 | 300 | 400 | 88 | 150 | 95 | M24 | +8/-12 |

| PKA 7-0 | 03/01/40 | 393 | 400 | 500 | 88 | 200 | 130 | M24 | +8/-14 |

| PKA 8-0 | 03/01/43 | 591 | 500 | 600 | 130 | 255 | 150 | M30 x 2 | +12/-15 |

Plastic injection moulding machines, die casting machines, plaining and slotting machines, cold extrusion machines, etc. Extreme slip resistance.

TOP FACE: Plain surface

BOTTOM FACE: Insulation pad B4

| Type | Item no. | max. load | L | B | H | d | e | Internal thread | Adjustment |

| PKA | Centre position | range | |||||||

| N/pc. | mm | mm | mm | mm | mm | mm | |||

| PKA 1-4 | 03/01/08 | 12 | 115 | 115 | 60 | 50 | 24 | M16 | +3/-3 |

| PKA 2-4 | 03/01/11 | 20 | 150 | 150 | 61 | 58 | 23 | M18 | +4/-4 |

| PKA 3-4 | 03/01/25 | 38 | 200 | 200 | 63 | 76 | 27 | M20 | +4/-6 |

| PKA 3/72-4 | 03/01/22 | 38 | 200 | 200 | 87 | 76 | 27 | M20 | +4/-7 |

| PKA 4-4 | 03/01/30 | 48 | 200 | 250 | 87 | 95 | 27 | M20 | +10/-7 |

| PKA 5-4 | 03/01/34 | 80 | 250 | 330 | 87 | 125 | 105 | M24 | +6/-10 |

| PKA 6-4 | 03/01/38 | 117.5 | 300 | 400 | 88 | 150 | 95 | M24 | +8/-12 |

| PKA 7-4 | 03/01/41 | 195.5 | 400 | 500 | 88 | 200 | 130 | M24 | +8/-14 |

| PKA 8-4 | 03/01/44 | 294.5 | 500 | 600 | 130 | 255 | 150 | M30 x 2 | +12/-15 |

Plastic injection moulding machines, die casting machines, plaining and slotting machines, cold extrusion machines, etc. Extreme slip resistance.

TOP FACE: Plain surface

BOTTOM FACE: Insulation pad B4

| PKA 1 -32 | 115 | 115 | 900 | 69 | 50/24 | M16 | +3/-3 |

|---|---|---|---|---|---|---|---|

| PKA 2 -32 | 150 | 150 | 1500 | 71 | 60/23 | M18 | +4/-4 |

| PKA 3-32 | 200 | 200 | 2800 | 72 | 75/27 | M20 | +4/-6 |

| PKA 4-32 | 200 | 250 | 3500 | 97 | 95/27 | M20 | +10/-7 |

| PKA 5-32 | 250 | 330 | 5800 | 98 | 125/105 | M24 | +6/-10 |

| PKA 6-32 | 300 | 400 | 9450 | 98 | 150/95 | M24 | +8/-12 |

| PKA 7-32 | 400 | 500 | 15700 | 98 | 200/130 | M24 | +8/-14 |

| PKA 8-32 | 500 | 600 | 23600 | 140 | 255/150 | M30 | +12/-15 |

Bolt-through Bilz precision levelling wedge PKD are used on machines that necessarily need to be anchored due to un-favourable centre of gravity proportions. Also for machines thatmust be pushed or pulled when levelling – and for machines with low intrinsic rigidity.

Bolts: Not supplied as a standard scope can be supplied on request

Note

Boring and cutting mills,machining centres, special machines, long bed lathers, long bed plaining machines.

TOP FACE:Plain surface

BOTTOM FACE: Insulation pad B0

| Type | max. load Kg/pc. | L | B | H | d | e | Drill hole | Adjustment range |

|---|---|---|---|---|---|---|---|---|

| mm | mm | Centre position mm | mm | mm | mm | |||

| PKD 1-0 | 2,500 | 115 | 115 | 60 | 50 | 24 | 22 | +4/-5 |

| PKD 2-0 | 4,300 | 150 | 150 | 61 | 58 | 23 | 23 | +5/-6 |

| PKD 3-0 | 7,700 | 200 | 200 | 63 | 76 | 27 | 26 | +3/-7 |

| PKD 3/72-0 | 7,700 | 200 | 200 | 87 | 76 | 27 | 26 | +4/-7 |

| PKD 4-0 | 9,700 | 200 | 250 | 87 | 95 | 27 | 26 | +10/-7 |

| PKD 5-0 | 16,100 | 250 | 330 | 87 | 125 | 105 | 30 | +6/-10 |

| PKD 6-0 | 23,600 | 300 | 400 | 88 | 150 | 95 | 30 | +8/-12 |

| PKD 7-0 | 39,300 | 400 | 500 | 88 | 200 | 130 | 35 | +8/-14 |

| PKD 8-0 | 59,100 | 500 | 600 | 130 | 255 | 150 | 35 | +12/-15 |

Bilz precision levelling wedge PKAK (bolt-on)/ PKDK (bolt-through) with spherical seat to compensate for angle differencesbetween machines and foundations, e.g. non processed machinemounts or uneven floors. Specifically for machines with a longbed and higher demands on geometry.

Note

TOP FACE SPHERICAL SEAT: Painted

BOTTOM FACE: Insulation pad B0

| Type | max. load | L | B | H | O/D | d | e | Internal Thread | Adjustment Range |

|---|---|---|---|---|---|---|---|---|---|

| Kg/pc | mm | mm | mm | mm | mm | mm | mm | ||

| PKAK 1-0 | 25,00 | 115 | 115 | 70 | 110 | 50 | 24 | M16 | +3/-3 |

| PKAK 2-0 | 43,00 | 150 | 150 | 77 | 150 | 58 | 23 | M18 | +4/-4 |

| PKAK 3-0 | 77,00 | 200 | 200 | 79 | 150 | 76 | 27 | M20 | +4/-6 |

| PKAK 4-0 | 97,00 | 200 | 250 | 103 | 150 | 95 | 27 | M20 | +10/-7 |

| Drill Hole | |||||||||

| PKDK 1-0 | 25,00 | 115 | 115 | 70 | 110 | 50 | 24 | 22 | +4/-5 |

| PKDK 2-0 | 43,00 | 150 | 150 | 77 | 150 | 58 | 23 | 23 | +5/-6 |

| PKDK 3-0 | 77,00 | 200 | 200 | 79 | 150 | 76 | 26 | 26 | +3/-7 |

| PKDK 4-0 | 97,00 | 200 | 250 | 103 | 150 | 95 | 27 | 26 | +10/-7 |

AMT MF series machine fixator is a one stop solution for precise yet cost efficient installation of heavy machinery and equipment. They are available in two basic designs: bolt-through and bolt-on. The “bolt-through” design has a clearance hole for an anchor bolt to securely anchor machines to the floor orfoundation.The”bolt-on”designcomeswithfastenersandisdesignedforfree-standing installations. MF series machine fixator is based on double wedge principle. Both wedges move towards or away from the loading center symmetrically. Equalizing these forces around the center results in an absolute rigid and stable anchoring system. As there is equal load distribution through two lifting wedges, the force required to raise or lower a machine is reduced considerably, resulting in effortless and precision leveling.

Application

Advantages

| Description | UOM | Product Code | ||

|---|---|---|---|---|

| AMT-MF 1 | AMT-MF 2 | AMT-MF 3 | ||

| Max Load per mount | kg | 2000 | 4000 | 5500 |

| permissible maximum load | kg | 12000 | 24000 | 36000 |

| Dimensional Data | ||||

| length x widthx Height ( LxBXH) | mm | 180x120x75 | 220x145x95 | 270x180x110 |

| Height Adjustment (h) | mm | 5 | 6 | 7 |

| Bolt through Size (?f) | mm | 24 | 28 | 37 |

| Bolt on size (M) | mm | M20 | M24 | M30 |

| Adjustment screw hex head (SW) | mm | 22 | 27 | 27 |

| Resting Diameter (D) | mm | 75 | 92 | 113 |

| c | mm | 32 | 34 | 43 |

| I | mm | 95 | 122 | 145 |

| e1 | mm | 14 | 18 | 22 |

| e2 | mm | 26 | 32 | 39 |

Our insulation washers for bolt heads offer adequate vibration and structure bornenoise insulation in rigidly anchored machines and components. They can be used at temperatures between -20 and +120 °C and are distinguishedby their high resistance to oils, greases, acids and coolants used in industry.

| for bolts | outer Ø | inner Ø | installation height | max. preload force | max.tightning torque |

|---|---|---|---|---|---|

| Ø | mm | mm | mm | kg | Nm |

| to M12 | 35 | 13 | 20 | 79 | 5 |

| to M20 | 50 | 21 | 22 | 150 | 16 |

| to M30 | 70 | 31 | 25 | 290 | 45 |

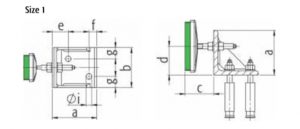

Size 2

Steel angle, Levelling elementType BNVS 115/5, 4 bolts M20 x 150, 3 anchors M20

| Type | Max. Load | a | b | c | d | e | f | g | i |

|---|---|---|---|---|---|---|---|---|---|

| kg/pc | mm | mm | mm | mm | mm | mm | mm | mm | |

| Size 1 | 1650 | 140 | 125 | 45 | 60-115 | 50 | 25 | 35 | 17.5 |

| Size 2 | 1650 | 160 | 180 | 55 | 60-140 | 48 | 45 | 37 | 22 |

Happy To Help!

Machine House (India) Pvt Ltd W-82(A), MIDC Ambad,Nashik – 422010

Designed by LBM Infotech Pvt. Ltd.

If you have any inquiries, Pls WhatsApp us