Levelling Elements

Bilz levelling elements are used for vibration and structure-borne noise insulatedmachine installation. The maintenance-free machine feet guarantee the simple andprecise levelling of machines and are available in many versatile designs.The sizes and insulation pads are selected according to the application and load. The range of levelling can be adapted depending on the selected bolt length and theindividual requirements.

General information

The type of insulation pads used can be found in the type description,e.g. BNSH 80/50 is equipped with B50, BNVS 50/30W with B30W etc.

Application : Specifically developed for the mounting of injection mouldingmachines, presses, punches etc. Optimum load distribution due to our provenpressure plate design. Very high horizontal stability over the entire levelling range.The BNSHA elements with bolt-on floor plate are particularly suitable for allmachines that tend to wander. The floor anchor is not used as a safeguard againsttipping.

| Type | Load | Type | Load | H | H | Type | Load | Type | Load | H | H | Ø D | Adjustment |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| BNSH / | Kg/pc | BNSH / | Kg/pc | BNSH With | BNSHA With | BNSH / | Kg/pc | BNSH / | Kg/pc | BNSH With | BNSHA With | Range | |

| BNSHA | BNSHA | B4 and B0 | B4 and B0 | BNSHA | BNSHA | B32 and B5 | B32 and B5 | MM | MM | ||||

| mm | mm | mm | mm | ||||||||||

| 70 / 4 | 300 | 70 / 0 | 720 | 25 | 29 | 70 / 32 | 275 | 70 / 5 | 500 | 40 | 44 | 80 | 6 |

| 80 /4 | 450 | 80 /0 | 940 | 40 | 44 | 80 /32 | 425 | 80 /5 | 800 | 44 | 48 | 96 | 12 |

| 100/4 | 700 | 100/0 | 1470 | 45 | 49 | 100/32 | 625 | 100/5 | 1175 | 49 | 53 | 113 | 12 |

| 120/4 | 1000 | 120/0 | 2100 | 45 | 49 | 120/32 | 900 | 120/5 | 1650 | 49 | 53 | 133 | 12 |

| 140/4 | 1375 | 140/0 | 2880 | 45 | 49 | 140/32 | 1225 | 140/5 | 2300 | 49 | 53 | 153 | 12 |

| 160/4 | 1800 | 160/0 | 3750 | 45 | 49 | 160/32 | 1600 | 160/5 | 3000 | 49 | 53 | 175 | 12 |

| 175/4 | 2150 | 175/0 | 4500 | 50 | 54 | 175/32 | 1900 | 175/5 | 3600 | 56 | 60 | 193 | 12 |

| 200/4 | 3100 | 200/0 | 5800 | 55 | 59 | 200/32 | 2500 | 200/5 | 5100 | 62 | 66 | 229 | 12 |

| 250/4 | 4400 | 250/0 | 9000 | 55 | 59 | 250/32 | 3900 | 250/5 | 7300 | 64 | 68 | 270 | 12 |

| Type | L | A | B | C | E | d |

|---|---|---|---|---|---|---|

| mm | mm | mm | mm | mm | mm | |

| BNSHA 70 | 125 | 15 | 75 | 105 | 8 | 5 |

| BNSHA 80 | 140 | 15 | 90 | 120 | 8 | 5 |

| BNSHA 100 | 160 | 15 | 110 | 140 | 11 | 5 |

| BNSHA 120 | 180 | 15 | 125 | 160 | 13 | 5 |

| BNSHA 140 | 200 | 15 | 150 | 180 | 16 | 5 |

| BNSHA 160 | 220 | 15 | 170 | 200 | 16 | 5 |

| BNSHA 175 | 260 | 20 | 185 | 230 | 20 | 8 |

| BNSHA 200 | 300 | 20 | 225 | 270 | 20 | 8 |

| BNSHA 250 | 330 | 20 | 265 | 300 | 20 | 8 |

| Type | Thread (G) | Pitch |

|---|---|---|

| BNSH / A 70 | M10 | 1.25 |

| BNSH / A 80 | M12 | 1.50 |

| BNSH / A 100 | M16 | 1.50 |

| BNSH / A 120 | M16 | 1.50 |

| BNSH / A 140 | M16 | 1.50 |

| BNSH / A 160 | M20 | 1.50 |

| BNSH / A 175 | M20 | 1.50 |

| BNSH / A 200 | M24 | 2.00 |

| BNSH / A 250 | M30 | 2.00 |

Application, Properties and bolts:

See type BNV/BNVS

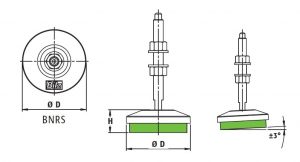

BNR/BNRS are used in cases where a firm connection of the element to the machine is desirable. Angle difference are equalized by means of the movable leveling screw.

| Type | Load | Type | Load | Type | Load | DIA | H | H |

|---|---|---|---|---|---|---|---|---|

| BNR / | Kg/pc | BNR / | Kg/pc | BNR / | Kg/pc | MM | MM | MM |

| BNRS | BNRS | BNRS | With B4/B0 | With B30W | ||||

| 50/4 | 170 | 50/0 | 340 | 50/30W | 60 | 60 | 21 | 24 |

| 65/4 | 300 | 65/0 | 630 | 65/30W | 120 | 74 | 21 | 24 |

| 70/4 | 360 | 70/0 | 720 | 70/30W | 140 | 85 | 25 | 28 |

| 80/4 | 420 | 80/0 | 840 | 80/30W | 160 | 87 | 25 | 28 |

| 95/4 | 700 | 95/0 | 1200 | 95/30W | 275 | 105 | 23 | 26 |

| 110/4 | 910 | 110/0 | 1820 | 110/30W | 350 | 121 | 29 | 32 |

| 150/4 | 1700 | 150/0 | 3400 | 150/30W | 690 | 163 | 32 | 35 |

| 175/4 | 2150 | 175/0 | 4100 | 175/30W | 850 | 190 | 30 | 33 |

| 200/4 | 3100 | 200/0 | 6200 | 200/30W | 1200 | 215 | 30 | 33 |

| 250/4 | 4400 | 250/0 | 8200 | 250/30W | 1700 | 253 | 37 | 40 |

Application: Proven and very effective plate element, preferably for lightto medium heavy machines with matching locating holes in the machinefeet. The BNV/BNVS elements are used where a rigid joint is required be-tween the machine and the fitting. Any unevenness or angular differencesin the floor up to ± 3° can be compensated for using the movable level-ling bolt.

| Type | Load | Type | Load | Type | Load | L | B | H | H |

|---|---|---|---|---|---|---|---|---|---|

| BNV/BNVS | Kg/pc | BNV/BNVS | Kg/pc | BNV/BNVS | Kg/pc | MM | MM | MM | MM |

| With B4/B0 | With B30W | ||||||||

| 50/4 | 200 | 50/0 | 400 | 50/30W | 95 | 60 | 60 | 21 | 24 |

| 80/4 | 470 | 80/0 | 950 | 80 /30W | 230 | 85 | 85 | 22 | 25 |

| 110/4 | 1200 | 110/0 | 2400 | 110/30W | 500 | 124 | 124 | 28 | 31 |

| 115/4 | 1140 | 115/0 | 2280 | 115/30W | 450 | 163 | 88 | 29 | 32 |

| 150/4 | 1800 | 150/0 | 3600 | 150/30W | 730 | 147 | 147 | 30 | 33 |

| 200/4 | 3700 | 200/0 | 7400 | 200/30W | 1500 | 264 | 165 | 35 | 38 |

Application: Food, luxury food, packaging, chemical and pharmaceutical industries as well as clean room applications.

Insulation pad properties:

B4: Medium hard pad with good vibration and structure-born BNRV noise insulation. Universal application.

B30W: Soft matching for a very good insulation effect, e.g. for grinding machines, test equipment, measuring machines, etc.

BR7: Anti-slip plate without vibration insulation.

| Type | Load | Type | Load | Type | Load | DIA | H | H |

|---|---|---|---|---|---|---|---|---|

| BNRSV | Kg/pc | BNRSV | Kg/pc | BNRSV | Kg/pc | MM | MM | MM |

| With B4/B0 | With B30W | |||||||

| 50/4 | 170 | 50/0 | 340 | 50/30W | 70 | 54 | 23 | 26 |

| 70/4 | 360 | 70/0 | 720 | 70/30W | 140 | 76 | 25 | 28 |

| 110/4 | 910 | 110/0 | 1820 | 110/30W | 350 | 116 | 27 | 30 |

| 150/4 | 1700 | 150/0 | 3400 | 150/30W | 690 | 156 | 29 | 32 |

AMT MM series machine mounts are well suited for mounting workshop machinery without being anchored to the ground especially for machines with high vertical and horizontal forces. These ready to install mounts allow immediate commissioning, eliminating the need for foundations or grouting. The height adjustment feature allows precise leveling of machinery. These mounts will insulate high frequency vibrations and sound and prevent wandering of machinery due to the large contact area. Also the anti vibration material used has high resistance to acids, alkalis and oils.

Application

Advantages

| Description | UOM | Product Code | |||

|---|---|---|---|---|---|

| AMT-MM1 | AMT-MM2 | AMT-MM3 | AMT-MM4 | ||

| Diameter (D) | mm | 80 | 120 | 160 | 200 |

| Height ( H) | mm | 45 | 45 | 56 | 68 |

| Stud Size (d) | mm | M12x1.5x110 | M16x1.5x110 | M20x1.5x160 | M20x1.5x160 |

| Adjustment (A) | mm | 12 | 15 | 21 | 21 |

| Min / Max Load per mount | kg | 50 – 500 | 200 – 1100 | 800 – 2100 | 1500 – 4000 |

AMT MH series machine mounts are ideal for machines exerting signivertical and horizontal forces, where a secure, high-precision connection with the machine is required. The unique design absorbs impulses and shock in high-speed machinery, where vibration damping is critical. Levelling accuracy of 1/100mm is achieved over the entire adjustment range. An integral locking device prevents the mount from coming apart during installation or relocation of the machine. It maintains excellent horizontal dynamic stability and provide vibration dampening during machine operation.

Application

Advantages

| Description | UOM | Product Code | |||

|---|---|---|---|---|---|

| AMT-MH1 | AMT-MH2 | AMT-MH3 | |||

| Diameter (D) | mm | 130 | 170 | 200 | |

| Height ( H) | mm | 62 | 62 | 62 | |

| Stud Size (d) | mm | M16x1.5x150 | M20x1.5x150 | M24x1.5x150 | |

| Adjustment (A) | mm | 19 | 22 | 22 | |

| Min / Max Load per mount | Kg | 50 – 500 | 200 – 1100 | 800 – 2100 | |

The AMT ML series leveling mounts are well equipped for many applications. These economical mounts provide fast, easy, and precise leveling. The unique design of connecting leveler and levelling stud is can automatically compensate ground unevenness of up to 4°. The anchor-free setup and the simple levelling with great levelling range guarantee maximum of your machinery.

Application

Advantages

| Description | UOM | Product Code | ||

|---|---|---|---|---|

| AMT-ML1 | AMT-ML2 | AMT-ML3 | ||

| Diameter (D) | mm | 85 | 135 | 175 |

| Height ( H) | mm | 19.5 | 25 | 26 |

| Stud Size (d) | mm | M12x1.75x100 LG | M16x1.5x120 LG | M20x1.5x150 LG |

| Max Load per mount | Kg | 650 | 1650 | 3000 |

Happy To Help!

Machine House (India) Pvt Ltd W-82(A), MIDC Ambad,Nashik – 422010

Designed by LBM Infotech Pvt. Ltd.

If you have any inquiries, Pls WhatsApp us